Collaboration: From Concept to Build

For many of our customers, the journey starts not with a precise specification or a fully formed plan, but with uncertainty. That’s where we come in.

PART ONE

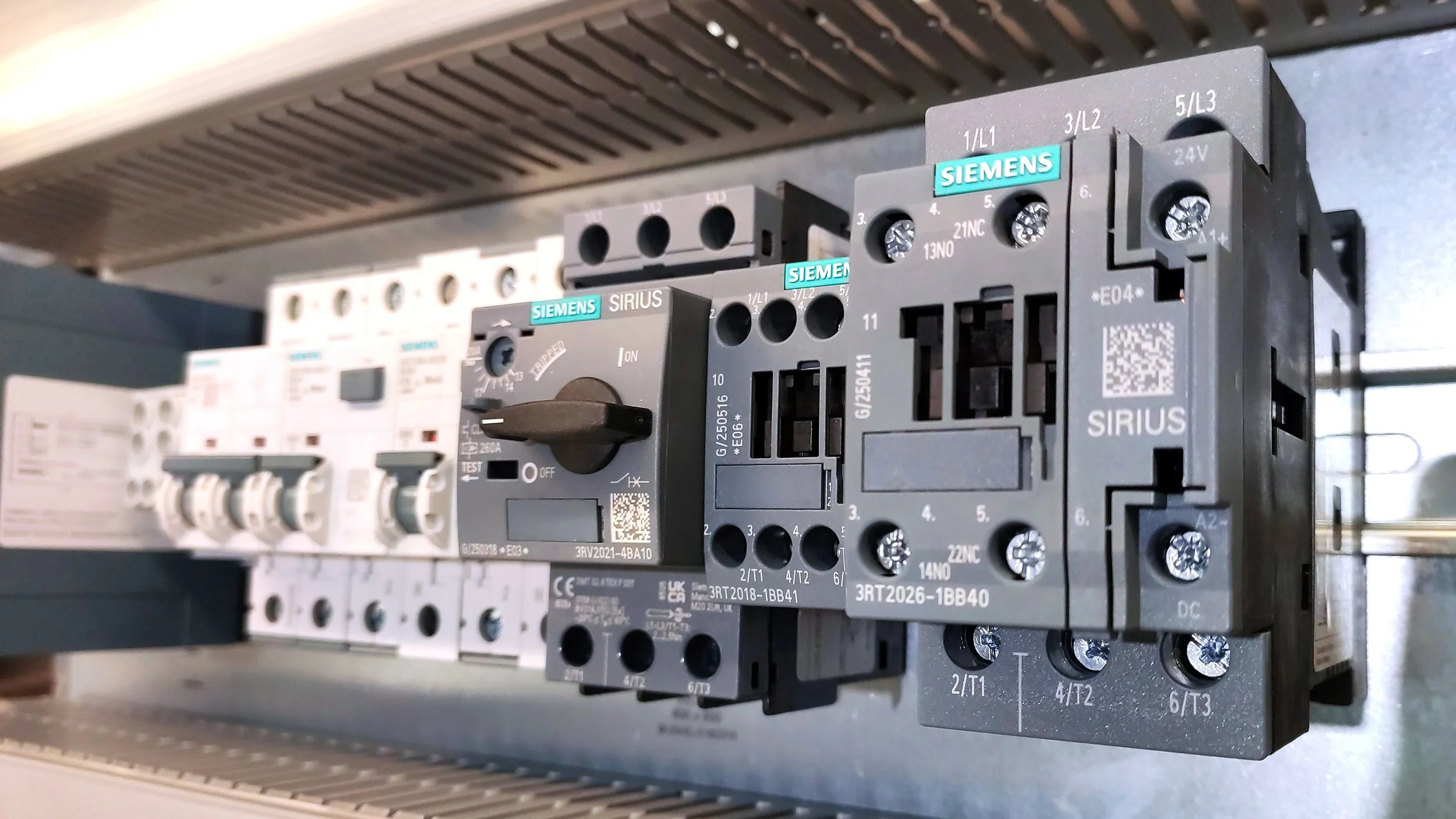

At Meson Electrical Services, and especially through our Meson Control offering, we take a collaborative approach. For many of our customers, the journey starts not with a precise specification or a fully formed plan, but with uncertainty. That’s where we come in.

When you don’t know what you need

Often, clients contact us when they’re unsure how to proceed. Perhaps they need a control system that needs to link into an existing installation, or they’re planning a new facility and only have a rough outline of requirements. We don’t just build panels and hand them over, we collaborate with you from first principles. That means listening, understanding your operation, considering safety, evaluating what’s possible, and offering design-led input.

Many businesses that wish to add new functionality to an existing control system without disturbing the current setup find themselves being recommended a full restart. But rejecting the older system and replacing it from scratch is not always the best solution. At Meson, we’re comfortable working with existing systems, including those where drawings or up-to-date documentation are not available. Our team is adept and experienced at piecing together how systems currently work and planning a path forward that minimises disruption.

Integration - seamlessly introducing new systems alongside the old

When legacy systems are still live, but no longer fit for future demands, we often propose a hybrid approach. We'll engineer a new system to run in parallel with the old one, interfacing carefully so both can operate together temporarily.

That’s because, when the time comes to decommission the old system, the groundwork is already laid for a smooth transition: the new control system is fully integrated, tested and understood. This reduces downtime and risk and avoids the ‘knee-jerk rebuild’ that many would opt for simply to avoid the hassle of reverse engineering.

Ready to Talk to Our Team Today?

PART TWO

“We need Meson”

When a project becomes complicated, especially where safety, hazardous environments or regulatory compliance are involved, bringing in experts makes all the difference. With nearly two decades of experience behind us, we often bring suggestions or ideas that customers didn’t even know existed.

In one recent case, a business we had worked with before brought us in when a control system underperformed and proved more complex than anticipated. Because of our depth of experience, we quickly devised a plan, laying out design options, safety considerations, and integration strategies, then shared it directly with the end client for sign-off.

The customer saved valuable time. Instead of needing to build system knowledge from the ground up, knowledge that takes years of hands-on experience, they knew they could trust us to deliver.

On-site detective work

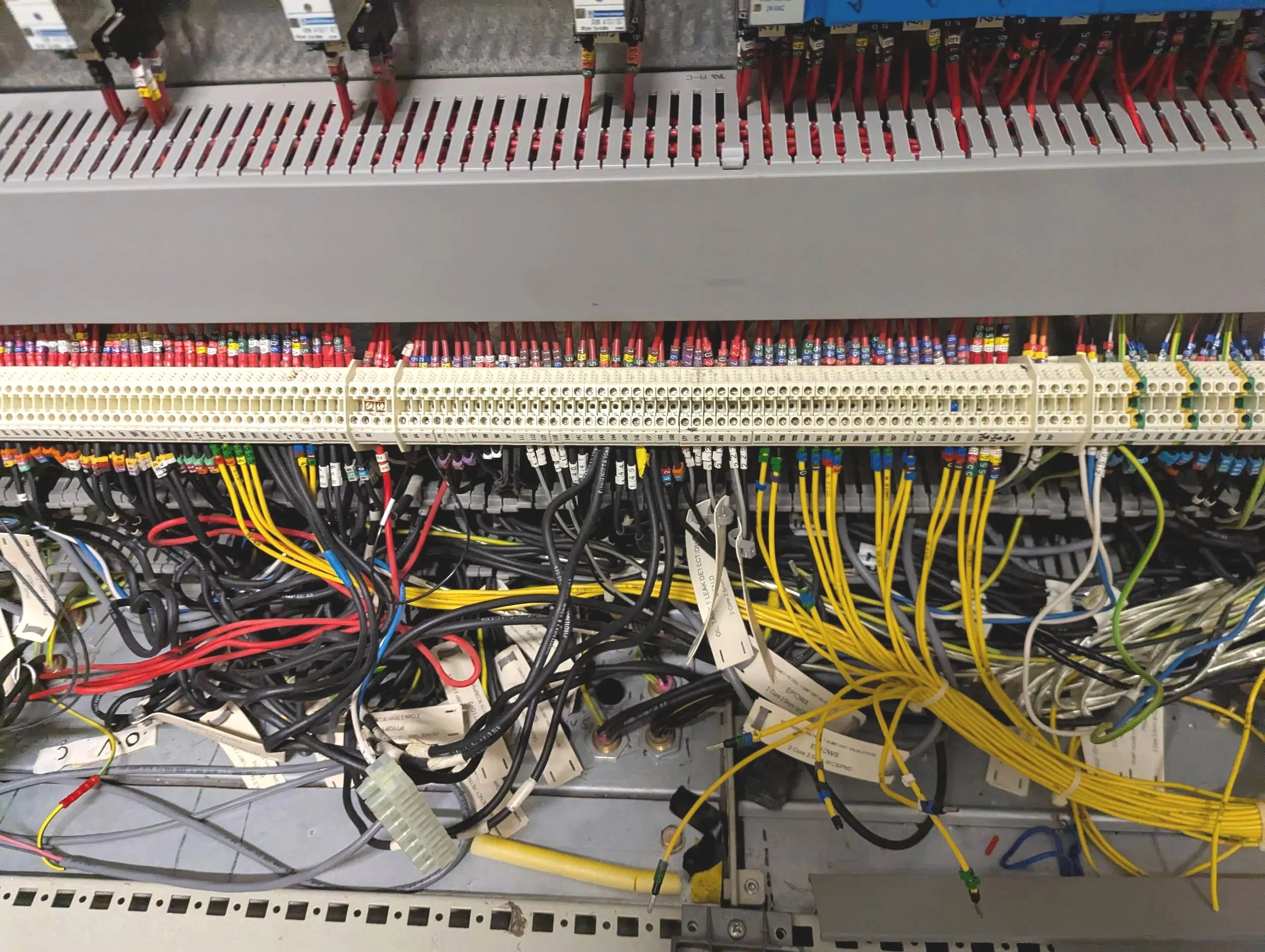

One of the greatest challenges with legacy control systems is that rarely do they come with full drawings or comprehensive specifications. That’s a major barrier for many integrators, but not for us.

Our engineers are accustomed to this kind of ‘detective work’. We’ll arrive on site, examine wiring, trace signals, and map out how the existing system behaves in practice. More than just the hardware, we take time to understand how your people use the system, what’s critical, and where you anticipate change. That way, when we design the new control architecture, it's built to work for you: now, and in the future.

We never assume that anyone, even within your team, has detailed control-system knowledge. Our role is to bridge the gap between what a system does today, and what you need it to do tomorrow.

Thinking about your Next System? Give us a Call:

PART THREE

Typical project workflow: from site visit to maintenance

A typical installation for us involves multiple key stages:

An initial site visit to assess existing systems, meet stakeholders and gather data.

Then a build phase off-site where we design, assemble and test the new control panel in our Yorkshire facility.

Finally, a installation and commissioning period to integrate the new system on site.

Once operational, maintenance becomes straightforward. For ATEX or hazardous-area installations, we recommend annual maintenance, typically a one-day visit, and we can also offer software updates and reactive support if needed.

If you or your client is facing uncertainty, tackling a legacy system, or need specialist expertise, we’re here to help. Get in touch with our team today.

“These guys know control. The team at Meson have repeatedly demonstrated their expertise in designing and delivering bespoke control systems tailored to complex project requirements.

Their in-depth knowledge of hazardous area installations has been invaluable, ensuring safety, compliance, and reliability across many of our projects over the years.

Their technical capability, attention to detail, and collaborative approach make them a trusted partner. It’s always a pleasure working alongside Meson.”

Tom Burns

Director, Octane Holding Group

Speak to our team today.

0113 286 4300

enquiries@mesonelectrical.com

WHO WE ARE

Our Goals

Team Values

Case Studies

News & Blogs